$114.00

Designed With a stylish appearance and new functional features, the RX II-132S is the top notch cutter in the market for professional sign makers. The brand new RX II-132S is among the best models for higher blade pressure, faster-cutting throughput, and precision of long tracking compared to same class models.

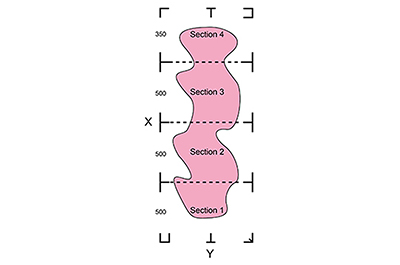

Section Cutting

Section cutting divides the long plot data into sectional output jobs to gain higher cutting quality and increase precision. GCC RX II series scan registration mark of section 1 and cut the plot data in section 1, and then it scan registration mark of section 2 and cut the plot data in section 2, and so on.

Section Cutting

Section cutting divides the long plot data into sectional output jobs to gain higher cutting quality and increase precision. GCC RX II series scan registration mark of section 1 and cut the plot data in section 1, and then it scan registration mark of section 2 and cut the plot data in section 2, and so on.

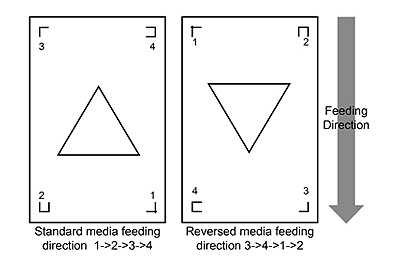

Auto Rotation

New registration marks defined to detect material feeding direction. RX II detects the unique registration marks to distinguish material feeding direction and rotate cutting content automatically. You don’t need to rotate the material by yourself.

Auto Rotation

New registration marks defined to detect material feeding direction. RX II detects the unique registration marks to distinguish material feeding direction and rotate cutting content automatically. You don’t need to rotate the material by yourself.

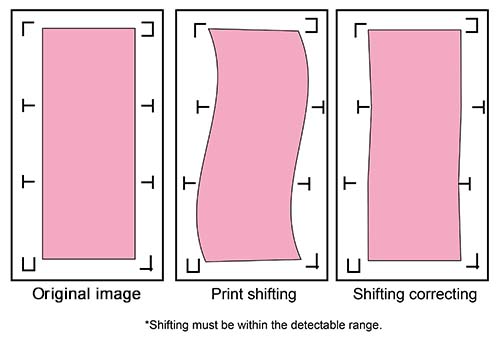

Segmental Positioning

RX II series features Segmental Positioning function which can correct the crooked print. Printed image may be crooked because the printing shifts, and Segmental Positioning function can scan the registration marks one by one automatically to calibrate shift.

Segmental Positioning

RX II series features Segmental Positioning function which can correct the crooked print. Printed image may be crooked because the printing shifts, and Segmental Positioning function can scan the registration marks one by one automatically to calibrate shift.

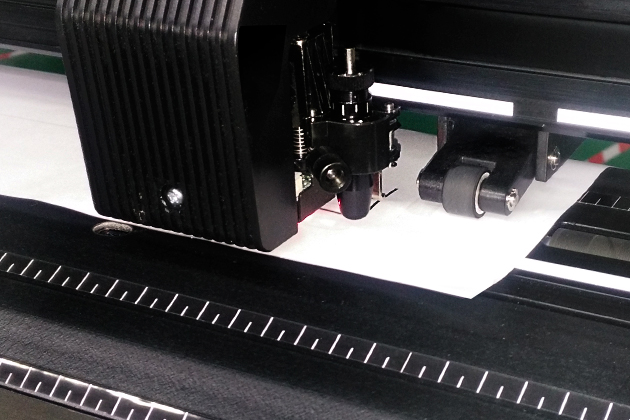

Enhanced AAS II Contour Cutting System

The RX II series features a standard Automatic-Aligning System (AAS II) to guarantee precise contour cutting by automatically detecting the registration marks on digitally produced images.

Enhanced AAS II Contour Cutting System

The RX II series features a standard Automatic-Aligning System (AAS II) to guarantee precise contour cutting by automatically detecting the registration marks on digitally produced images.

1st-mark auto-detection 1st-mark auto-detection |

4-point positioning 4-point positioning |

Segmental positioning Segmental positioning |

Multiple copies Multiple copies |

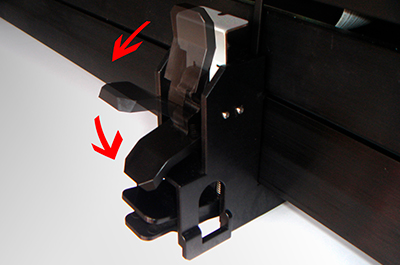

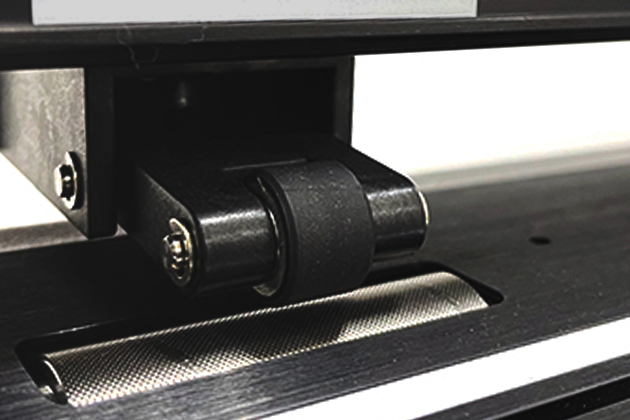

Multiple Pressure Pinch Rollers for Different Media

The Multi-Pressure Pinch Rollers give users three pressure settings to better cater to the different types of media that they are working with. The following shows suitable settings for some materials.

Multiple Pressure Pinch Rollers for Different Media

The Multi-Pressure Pinch Rollers give users three pressure settings to better cater to the different types of media that they are working with. The following shows suitable settings for some materials.

| Materials | Left side | Middle | Right side |

| Sandblast mask, Reflective film | Heavy | Medium | Heavy |

| Vinyl | Medium | Medium | Medium |

| Window tinting film | Medium | Light | Medium |

Triple Port Connectivity

RX II series supports triple port connectivity with USB, serial and Ethernet ports. The USB port provides faster and convenient data transmission between the computer and RX II. Ethernet connection enables multiple RX II to be operated by one PC and multiple PCs to share a single unit. Triple port connectivity provides sign makers a great flexibility for data transmission.

Triple Port Connectivity

RX II series supports triple port connectivity with USB, serial and Ethernet ports. The USB port provides faster and convenient data transmission between the computer and RX II. Ethernet connection enables multiple RX II to be operated by one PC and multiple PCs to share a single unit. Triple port connectivity provides sign makers a great flexibility for data transmission.

Auto Cut Off

This features allows users to set the cutter to cut off the media after the completion of each job, making it easy to set up an unattended workflow for mass production. Or user can simply push the “Cut off” button after the completion of a job to have the media cut off automatically.

Auto Cut Off

This features allows users to set the cutter to cut off the media after the completion of each job, making it easy to set up an unattended workflow for mass production. Or user can simply push the “Cut off” button after the completion of a job to have the media cut off automatically.

Touch Key Panel & Backlight LCM

The brand new touch key panel is easy to use and durable. The intuitive design allows new users to operate the machine easily. The easy-to-use and multi-language touch key panel can remarkably simplify complex tasks. Backlight LCM makes users can recognize the text on the panel more easily.

Touch Key Panel & Backlight LCM

The brand new touch key panel is easy to use and durable. The intuitive design allows new users to operate the machine easily. The easy-to-use and multi-language touch key panel can remarkably simplify complex tasks. Backlight LCM makes users can recognize the text on the panel more easily.

Efficient Throughput

At up to 60 inches per second of cutting speed, RX II series cutting throughput simply outperforms the competition.

Efficient Throughput

At up to 60 inches per second of cutting speed, RX II series cutting throughput simply outperforms the competition.

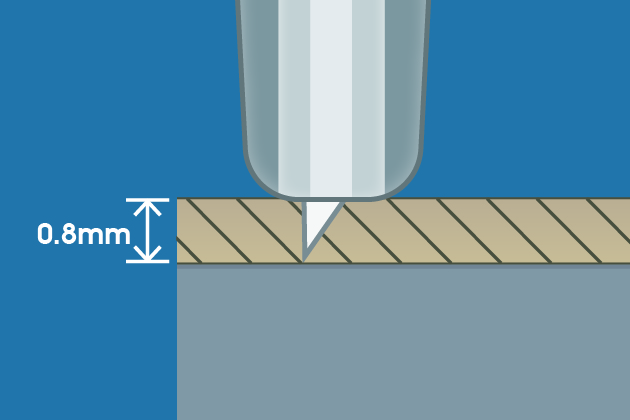

600 Grams of Cutting Force

Selectable cutting forces, ranging from 5 to 600g, accommodate a wide variety of materials, including fine and thin masking films to thick and hard reflective films.

600 Grams of Cutting Force

Selectable cutting forces, ranging from 5 to 600g, accommodate a wide variety of materials, including fine and thin masking films to thick and hard reflective films.

Innovative Tangential Mode

The tangential mode performs clean cuttings, diminutive letterings and intricate graphics which yield smooth corners and sleek edges on thick materials.

Innovative Tangential Mode

The tangential mode performs clean cuttings, diminutive letterings and intricate graphics which yield smooth corners and sleek edges on thick materials.

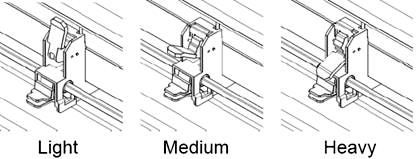

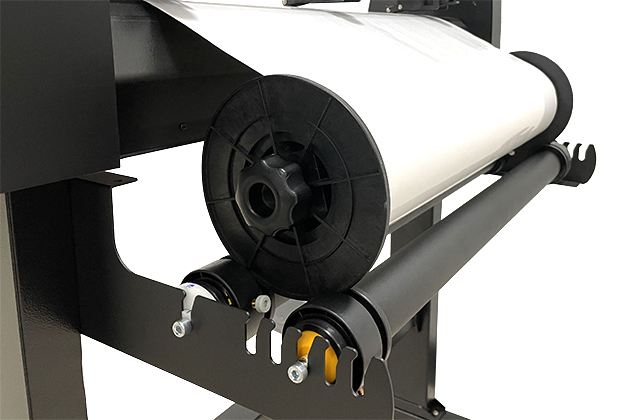

Media Support System

The media support system is fully adjustable. It supports media on standard cores and resolves media drifting and alignment problems to ensure better tracking.

Media Support System

The media support system is fully adjustable. It supports media on standard cores and resolves media drifting and alignment problems to ensure better tracking.

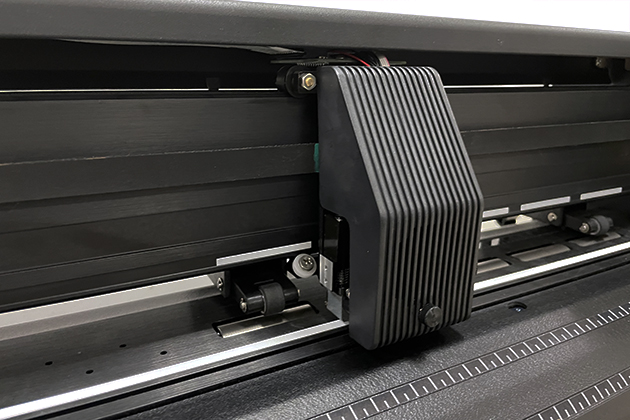

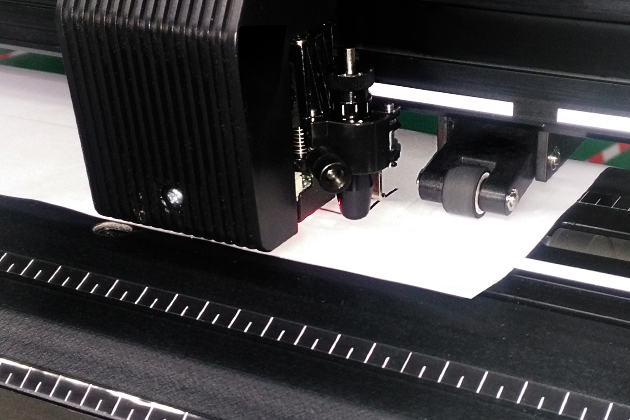

Handy Grooved Cut Off Tool

This handy and innovative design allows you to cut off a finished job in a straight line easily, reducing the possibility of wasting usable material.

Handy Grooved Cut Off Tool

This handy and innovative design allows you to cut off a finished job in a straight line easily, reducing the possibility of wasting usable material.

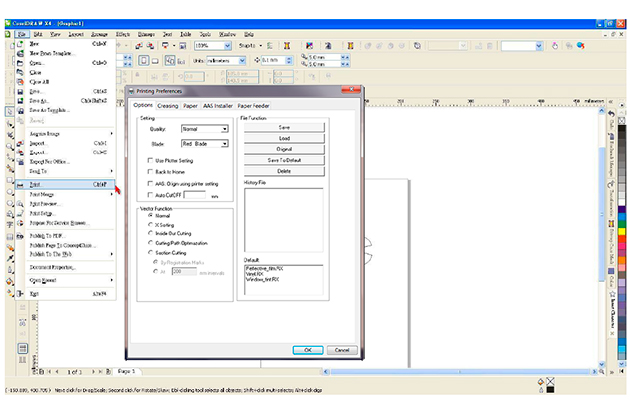

Advanced One Click Driver

RX II series includes a Windows driver that allows sign makers to edit signs from CorelDRAW and output directly to the RX II series cutters. The One Click Driver simplifies the driver installation process. You just double click on the driver installation icon and the program will take care of the rest.

Advanced One Click Driver

RX II series includes a Windows driver that allows sign makers to edit signs from CorelDRAW and output directly to the RX II series cutters. The One Click Driver simplifies the driver installation process. You just double click on the driver installation icon and the program will take care of the rest.

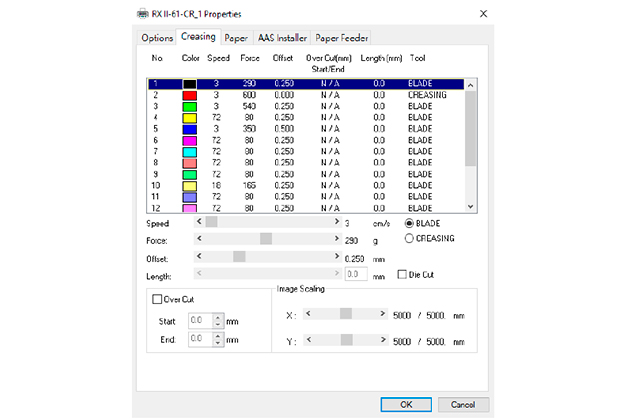

Multiple Parameters Setting by 16 Different Colors

The new interface allows users to set up multiple parameters by using different color lines. This gives the operator greater flexibility when setting up a job.

Multiple Parameters Setting by 16 Different Colors

The new interface allows users to set up multiple parameters by using different color lines. This gives the operator greater flexibility when setting up a job.

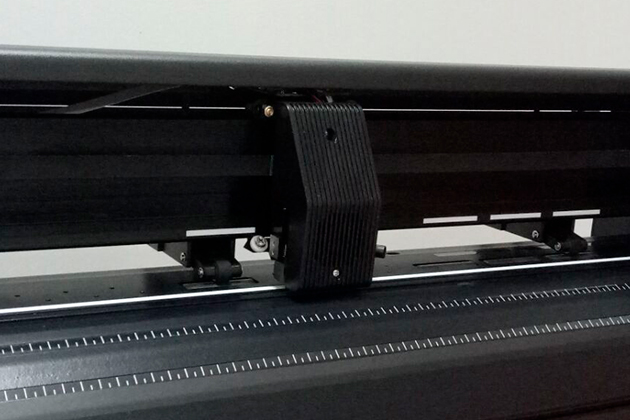

Selective Pinch Roller Positioning

Each pinch roller can be positioned and operated individually, widening the RX II series cutting plotters’ range of applications.

Selective Pinch Roller Positioning

Each pinch roller can be positioned and operated individually, widening the RX II series cutting plotters’ range of applications.

Guaranteed 10m Tracking Ability

The exclusive grid drum and precisely engineered mechanism to provide superb tracking ability.

Guaranteed 10m Tracking Ability

The exclusive grid drum and precisely engineered mechanism to provide superb tracking ability.

Visit Us To Take Advantage Of Exclusive Showroom Deals:

1300 Alness St, Concord, ON L4K 2W6

We Offer the Lowest Copier Prices in Toronto

Call For Same Day Quote! (905) 326-2790